| Technical Specifications | |||||||||||||||||

| Model | DXY-PA20 | DXY-PA30 | DXY-PA40 | DXY-PA50 | DXY-PA60 | DXY-PA80 | DXY-PA100 | DXY-PA120 | DXY-PA150 | DXY-PA200 | DXY-PA250 | DXY-PA300 | DXY-PA400 | DX-500 | DX-600 | ||

| Cooling capacity | kcal/h | 4500 | 6500 | 8000 | 12000 | 15000 | 18000 | 24000 | 30000 | 40000 | 50000 | 60000 | 80000 | 100000 | 120000 | 140000 | |

| KW | 5 | 7.5 | 9.5 | 15 | 17 | 21 | 28 | 35 | 45 | 58 | 70 | 92 | 116 | 139 | 162 | ||

| BTU/H | 19000 | 27900 | 33000 | 50000 | 58000 | 71000 | 95000 | 115000 | 125800 | 197000 | 240000 | 310000 | 394000 | 480000 | 550000 | ||

| Temp. control range | ℃ | Thermostatic(setting range:20~50℃) | |||||||||||||||

| Conditions | Ambient temp. | -10℃-45℃ | |||||||||||||||

| Oil temp. | ℃ | 10-55℃ | |||||||||||||||

| Oil type | Hydraulic oil / Spindle oil / Cutting oil / Heat transfer oil | ||||||||||||||||

| Oil viscosity | Cst | 20-100(≥100: please consult Dongxu for special order) | |||||||||||||||

| Input power | V | Three-phase four-wire | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | |

| Total power | KW | 2.5 | 3.5 | 4.5 | 6 | 7 | 9.5 | 12 | 15 | 19 | 21 | 25 | 30 | 42 | 50 | 61 | |

| Compressor | Power supply | v | 220V | 380V | 380V | 380V | 380V | 380V | 380V | 380V | 380V | 380V | 380V | 380V | 380V | 380V | 380V |

| Power | KW | 1.5 | 2.5 | 3 | 3.75 | 4.5 | 6.5 | 7.5 | 10 | 12.5 | 16 | 19 | 23 | 31 | 38 | 46 | |

| Oil pump | Power | KW | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 3 | 3 | 3 | 4 | 4 | 5.5 | 7.5 | 11 |

| Flow | L/min | 25 | 35 | 40 | 50 | 63 | 100 | 100 | 125 | 160 | 250 | 300 | 350 | 450 | 500 | 550 | |

| Piping size(Flange) | mm | ZG1" | ZG1" | ZG1" | ZG1¼" | ZG1¼" | ZG1½" | ZG1½" | ZG2" | ZG2" | DN50 | DN65 | DN65 | DN80 | DN80 | DN100 | |

| Dimension | Height:B | mm | 1070 | 1235 | 1235 | 1760 | 1760 | 1760 | 1760 | 1680 | 1820 | 1865 | 1925 | 1965 | 2290 | 2290 | 2290 |

| Width :C | mm | 600 | 600 | 600 | 700 | 700 | 830 | 830 | 755 | 900 | 1060 | 1060 | 1100 | 1200 | 1200 | 1200 | |

| Length:D | mm | 700 | 700 | 700 | 800 | 800 | 800 | 800 | 1360 | 1520 | 1750 | 1950 | 2250 | 2400 | 2400 | 2400 | |

| Net weight | kg | 120 | 144 | 150 | 206 | 210 | 290 | 300 | 336 | 370 | 540 | 600 | 720 | 1000 | 1100 | 1200 | |

| Refrigerant | Refrigerant:R22/R407C | ||||||||||||||||

| Protective device | ☆ Phase loss protection ☆ Motor reverse phase sequence protection ☆ Compressor overload protection ☆ Oil pump overload protection ☆ High and low pressure protection ☆ Abnormal alarm | ||||||||||||||||

1. The foundation of the cooler must be enough to prevent the equipment from sinking, and there should be enough space at the end of the fixed hole pan head cover. In order to pull out the tube bundle from the shell, the equipment should be installed according to the hoisting specification. After the level is aligned, tighten the anchor screws to connect the inlet and outlet pipes of the cold and hot medium. 2. The air in the cavity should be exhausted before the cooler is started to improve the heat transfer efficiency. The steps are as follows: 1) Loosen the vent plugs on the hot and cold medium ends, and close the medium discharge valve; 2) Slowly open the water inlet valve of the hot and cold medium until the hot and cold medium overflows from the air vent, then tighten the air vent plug and close the water inlet valve. 3. When the water temperature rises by 5-10°C, open the water inlet valve of the cooling medium (Note: Do not open the water inlet valve quickly. When a large amount of cooling water flows through the cooler, it will cause a long-term formation on the surface of the heat exchanger. The "supercooled layer" with poor thermal conductivity of the layer), and then open the inlet and outlet valves of the heat medium to make it in a flowing state, and then pay attention to adjusting the flow rate of the cooling medium to keep the heat medium at the best operating temperature. 4. If galvanic corrosion occurs on one side of the cooling water, a zinc rod can be installed at the designated position. 5. Before the dirty medium passes through the cooler, a filter device should be provided. 6. The pressure of the cooled medium should be greater than the pressure of the cooling medium. ◆There are two control modes of constant temperature and room temperature coherence, users can choose according to actual needs. ◆Have a variety of protection functions and provide passive alarm terminals, real-time alarm for fault signals, and can also be connected to industrial equipment to provide alarm functions. ◆It has the functions of real-time temperature monitoring, high oil temperature early warning, alarm, and low oil temperature alarm functions, which can maintain the viscosity characteristics of the oil and make the machine run stably. ◆The main engine adopts famous brand compressors imported from Europe, America and Japan, with reliable operation, high efficiency and low noise. ◆Imported high-quality oil pump with high pressure, high stability and long-lasting durabilty. ◆Imported digital controller with high precision and wide aplication range. ◆To avoid the influence of the precision of the machine due to the change of oil temperature during work. ◆To avoid the deterioration of oil products due to high temperature, keep the oil viscosity unchanged, and make the machine work stably during work. ◆The oil temperature control is based on human body temperature (indoor temperature). Customers can set the oil temperature according to the human body temperature to avoid thermal deformation caused by the mechanical structure.

1. The foundation of the cooler must be enough to prevent the equipment from sinking, and there should be enough space at the end of the fixed hole pan head cover. In order to pull out the tube bundle from the shell, the equipment should be installed according to the hoisting specification. After the level is aligned, tighten the anchor screws to connect the inlet and outlet pipes of the cold and hot medium. 2. The air in the cavity should be exhausted before the cooler is started to improve the heat transfer efficiency. The steps are as follows: 1) Loosen the vent plugs on the hot and cold medium ends, and close the medium discharge valve; 2) Slowly open the water inlet valve of the hot and cold medium until the hot and cold medium overflows from the air vent, then tighten the air vent plug and close the water inlet valve. 3. When the water temperature rises by 5-10°C, open the water inlet valve of the cooling medium (Note: Do not open the water inlet valve quickly. When a large amount of cooling water flows through the cooler, it will cause a long-term formation on the surface of the heat exchanger. The "supercooled layer" with poor thermal conductivity of the layer), and then open the inlet and outlet valves of the heat medium to make it in a flowing state, and then pay attention to adjusting the flow rate of the cooling medium to keep the heat medium at the best operating temperature. 4. If galvanic corrosion occurs on one side of the cooling water, a zinc rod can be installed at the designated position. 5. Before the dirty medium passes through the cooler, a filter device should be provided. 6. The pressure of the cooled medium should be greater than the pressure of the cooling medium. ◆There are two control modes of constant temperature and room temperature coherence, users can choose according to actual needs. ◆Have a variety of protection functions and provide passive alarm terminals, real-time alarm for fault signals, and can also be connected to industrial equipment to provide alarm functions. ◆It has the functions of real-time temperature monitoring, high oil temperature early warning, alarm, and low oil temperature alarm functions, which can maintain the viscosity characteristics of the oil and make the machine run stably. ◆The main engine adopts famous brand compressors imported from Europe, America and Japan, with reliable operation, high efficiency and low noise. ◆Imported high-quality oil pump with high pressure, high stability and long-lasting durabilty. ◆Imported digital controller with high precision and wide aplication range. ◆To avoid the influence of the precision of the machine due to the change of oil temperature during work. ◆To avoid the deterioration of oil products due to high temperature, keep the oil viscosity unchanged, and make the machine work stably during work. ◆The oil temperature control is based on human body temperature (indoor temperature). Customers can set the oil temperature according to the human body temperature to avoid thermal deformation caused by the mechanical structure.Internal and outer diameter grinding equipment

In order to maintain the operating efficiency of the oil-cooled unit and prolong its service life, regular maintenance and maintenance work should be carried out. Any maintenance and maintenance must be carried out under power-off conditions, and should be 1-2 hours after the unit stops running. 1. Turn on the oil cooler. From March to November each year, the operator is required to turn on the oil cooler in time to ensure the normal operation of the equipment, and it is stipulated that the oil cooler should be turned on when the equipment is started every shift. 2. Observation of oil cooler. The oil cooler is set with a certain refrigeration temperature value. When operating the equipment, the operator should pay attention to the display value of the oil temperature. When the oil temperature is higher than the set value for a long time, you need to report the situation to maintenance in time. 3. Clean the fuel tank. The oil cooler runs for about 3-5 months, and the oil in the oil tank is filtered. At the same time, clean the bottom of the fuel tank completely. In order to prevent the oil from being too dirty to block the oil suction port of the oil cooler, the refrigeration efficiency is poor, and no oil enters the oil cooler oil pump, damaging the oil cooler oil pump, and freezing the evaporator of the oil cooler. 4. Clean the air filter. Clean the air filter every two weeks (at least once a week when the environment is harsh). When cleaning, remove the filter first, and use a vacuum cleaner or an air spray gun to remove dust. When the dirt is serious, the air filter should be cleaned with warm water and neutral detergent at a temperature not exceeding 40°C. After cleaning, the water should be air-dried and then reinstalled. 5. Regular inspections. According to the cleanliness of the oil, regularly check and clean the oil suction filter or replace the filter to prevent clogging by dirt. 6. Clean the surface of the unit. When the surface of the unit is dirty, it should be cleaned with a soft cloth with neutral detergent or high-quality soapy water. Be careful not to use petroleum, acid solvents, grinding powder, steel brushes, sandpaper, etc., to prevent damage to the plastic spray surface. 7. Check before reuse. After long-term re-use or use for a long period of time, check whether the heat exchanger of the oil cooler is blocked by dust or dirt. If necessary, use dry compressed air, a vacuum cleaner or a soft brush to clean the surface. Be careful not to damage the heat exchanger fins during this work.

In order to maintain the operating efficiency of the oil-cooled unit and prolong its service life, regular maintenance and maintenance work should be carried out. Any maintenance and maintenance must be carried out under power-off conditions, and should be 1-2 hours after the unit stops running. 1. Turn on the oil cooler. From March to November each year, the operator is required to turn on the oil cooler in time to ensure the normal operation of the equipment, and it is stipulated that the oil cooler should be turned on when the equipment is started every shift. 2. Observation of oil cooler. The oil cooler is set with a certain refrigeration temperature value. When operating the equipment, the operator should pay attention to the display value of the oil temperature. When the oil temperature is higher than the set value for a long time, you need to report the situation to maintenance in time. 3. Clean the fuel tank. The oil cooler runs for about 3-5 months, and the oil in the oil tank is filtered. At the same time, clean the bottom of the fuel tank completely. In order to prevent the oil from being too dirty to block the oil suction port of the oil cooler, the refrigeration efficiency is poor, and no oil enters the oil cooler oil pump, damaging the oil cooler oil pump, and freezing the evaporator of the oil cooler. 4. Clean the air filter. Clean the air filter every two weeks (at least once a week when the environment is harsh). When cleaning, remove the filter first, and use a vacuum cleaner or an air spray gun to remove dust. When the dirt is serious, the air filter should be cleaned with warm water and neutral detergent at a temperature not exceeding 40°C. After cleaning, the water should be air-dried and then reinstalled. 5. Regular inspections. According to the cleanliness of the oil, regularly check and clean the oil suction filter or replace the filter to prevent clogging by dirt. 6. Clean the surface of the unit. When the surface of the unit is dirty, it should be cleaned with a soft cloth with neutral detergent or high-quality soapy water. Be careful not to use petroleum, acid solvents, grinding powder, steel brushes, sandpaper, etc., to prevent damage to the plastic spray surface. 7. Check before reuse. After long-term re-use or use for a long period of time, check whether the heat exchanger of the oil cooler is blocked by dust or dirt. If necessary, use dry compressed air, a vacuum cleaner or a soft brush to clean the surface. Be careful not to damage the heat exchanger fins during this work.Hydraulic press

High-speed punching machine

CNC machine tools

Charge and discharge processing equipment

Hydraulic machinery

Wind power station

Deep hole drill

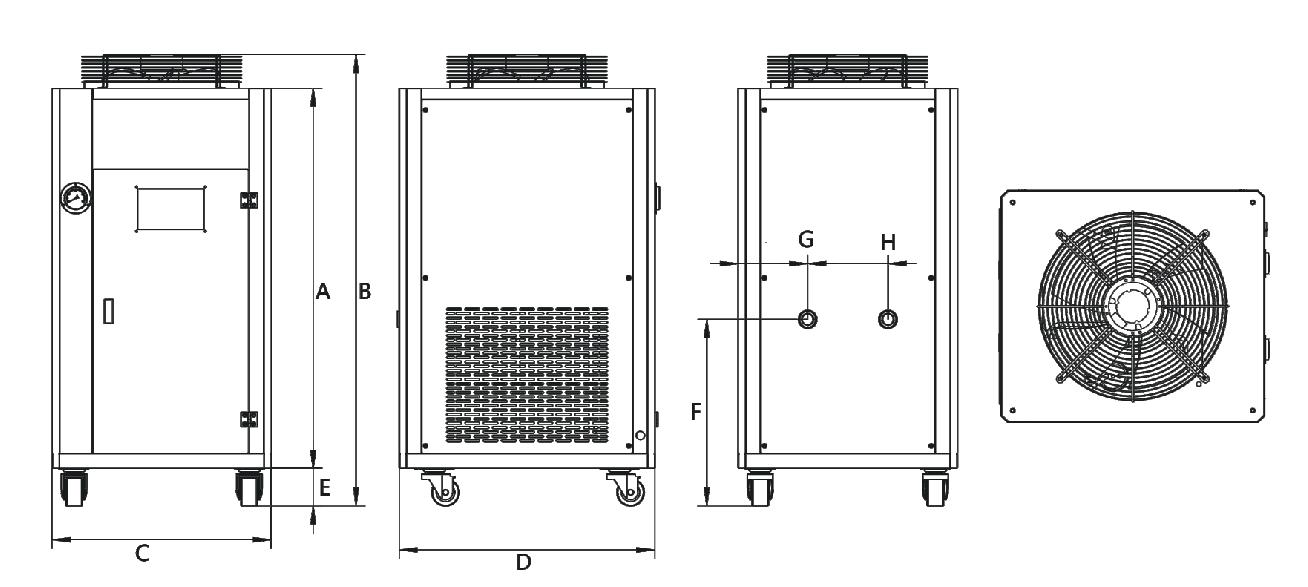

| Mounting Dimensions | |||||||||||||||

| Model | DXY-PA20 | DXY-PA30 | DXY-PA40 | DXY-PA50 | DXY-PA60 | DXY-PA80 | DXY-PA100 | DXY-PA120 | DXY-PA150 | DXY-PA200 | DXY-PA250 | DXY-PA300 | DXY-PA400 | DX-500 | DX-600 |

| A(mm) | 891 | 1041 | 1041 | 1663 | 1663 | 1559 | 1559 | 1494 | 1551 | 1750 | 1800 | 1853 | 2165 | 2165 | 2165 |

| B(mm) | 1070 | 1235 | 1235 | 1760 | 1760 | 1760 | 1760 | 1680 | 1820 | 1865 | 1925 | 1965 | 2290 | 2290 | 2290 |

| C(mm) | 600 | 600 | 600 | 700 | 700 | 830 | 830 | 755 | 900 | 1060 | 1060 | 1100 | 1200 | 1200 | 1200 |

| D(mm) | 700 | 700 | 700 | 800 | 800 | 800 | 800 | 1360 | 1520 | 1750 | 1950 | 2250 | 2400 | 2400 | 2400 |

| E(mm) | 104 | 104 | 104 | 104 | 104 | 104 | 104 | 104 | 103 | 241 | 245 | 248 | 249 | 249 | 249 |

| F(mm) | 502 | 512 | 512 | 499 | 499 | 604 | 604 | 296 | 333 | 547 | 561 | 585 | 587 | 587 | 587 |

| G(mm) | 190 | 190 | 190 | 243 | 243 | 264 | 264 | 171 | 433 | 238 | 246 | 250 | 273 | 273 | 273 |

| H(mm) | 220 | 220 | 220 | 220 | 220 | 300 | 300 | 230 | 224 | ||||||

Deep hole drill

Lubrication station equipment

CNC cutting machine

Hydraulic press

High-speed turret punch

Hydraulic machinery

Boring machine